Block Bottom Bags

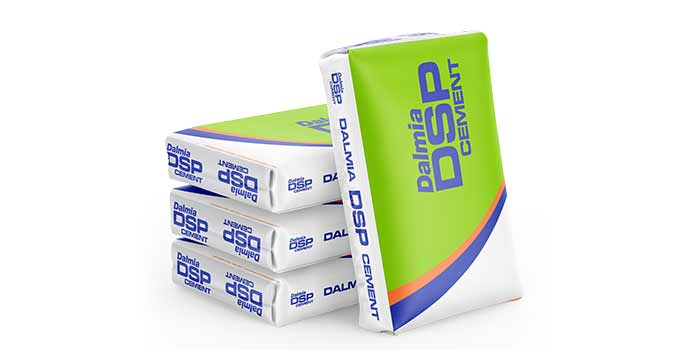

Block Bottom Bags are also known as AD*STAR Bags which are ideal for automated filling have distinctive design of sturdy bottom which make this bag great stability and can stand-up securely. It is used for packing materials like cement, flour etc. and act as better substitute to the paper bags. In addition, our block bottom bags are ideal for different sectors mentioned in the application section. The brick-shaped PP woven sacks are produced without adhesives by heat-welding of the coating on the fabric.

We manufacture and supply Block Bottom Bags in diverse sizes, in different colours, diverse inner and outer finish designs that are air-resistant and moisture-proof and recyclable for our customers all over the globe. These and eco-friendly bags and their manufacturing process includes diverse plastic materials like MET, PE, PPE, BOPP and LLDPE. Our production capacity is to the tune of 2.5 lakh bags per day for AD Star/Block Bottom/BOPP/LPP Bags and 30 ton per month for other packaging materials.

Bright’s BBB Bag Available Exclusively In

- Lamination

- Flexographic printing up to 8 colours

- BOPP printing up to 8 colours

- Matt /Glossy Effect

Features

- 100% customized PP Sack with any customized size, colour, GSM

- UV Protection from 200 to 1600 Hours

- Valve for easy filling

- Recyclable

- High strength & Increased tear resistance

- Inside and outside Lamination as per the customers requirement

- Cannot be tampered as is hermetically sealed

Application Industries

- Building materials,

- Food products,

- Chemical,

- Agricultural, etc.

For Packing

- Concrete materials,

- Cement,

- chemicals,

- Resin,

- Polymer,

- Granules,

- PVC compound,

- Masterbatches,

- Carbon,

- Agriculture & farming,

- Fertilizers,

- Urea,

- Minerals,

- Sugar,

- Salt,

- Seeds,

- Spices,

- Agro products,

- Cashew nuts,

- Dates,

- Barely,

- Flour,

- Rice,

- Corn

- Food grains.